[ux_image id=”24539″ height=”50%” lightbox=”true” caption=”true” image_hover=”fade-in” image_hover_alt=”zoom”]

[gap]

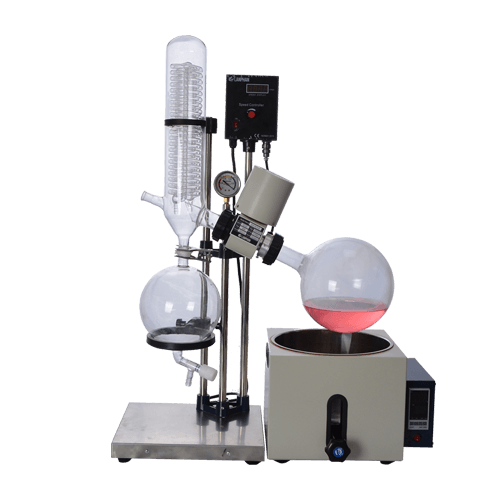

The maintenance of a rotary evaporator is of great significance to prolong the service life of the instrument and keep the instrument in good working condition. A rotary evaporator should be kept dry and clean in routine work. Quickly remove the spilled liquid and clean the outer surface of the rotary evaporator by using a non-abrasive cleaner. Besides, what other matters should be specifically paid attention to in the maintenance of a rotary evaporator?

Maintenance Knowledge of a Rotary Evaporator

- The internal devices of the magnetic stirrer on the rotary evaporation instrument have an upper limit of heating. Therefore, it must be taken into account when heating, to ensure that the machine can be heated properly. Remember to change the state of the motor to the state of rotation, so as to protect the magnetic stirrer to the greatest extent.

- In order to ensure that the rotary evaporator is not damaged, there are usually insulating materials inside the instrument. When the magnetic stirrer on the rotary evaporator is used at the first time, we will find a little white smoke or pungent smell. These are normal phenomena, not product quality problems, as long as we keep ventilation.

- When the heating is done, be sure to turn off the heat and wait 3-5 minutes for the temperature to drop before turning off the stirring.

- Do any repair or inspection to the machine, be sure to cut off the power supply, water. Note: this equipment belongs to fragile products. Please handle it carefully when using it. The damage of fragile products is not covered by our warranty.

- Regularly clean the seal by removing the seal and checking for dirt on the shaft. Wipe it off with a soft cloth, then apply a little vacuum grease and reinstall it to keep the shaft and seal slipper.

- Wipe each interface with soft cloth(Use napkins instead),then paint a little vacuum grease.The vacuum grease must be well covered after use to prevent lime sand from entering.

- The interfaces shall not be screwed too tightly, and shall be loosened regularly to avoid the death of the connector caused by long-term locking.

- Turn off the power supply, then let the machine run from slow to fast,When the machine is stopped, the switch should be switched off.

- The teflon switches in various places cannot be tightened with excessive force, which is easy to damage the glass.

- After each use we must use a soft cloth to wipe all kinds of oil stains, stains, solvents left on the surface of the machine, keep clean.

- After the machine is stopped, loosen the teflon switches. The teflon piston will be deformed if the teflon switch is in a static working state for a long time.

- Do not allow water to enter the electrical part. Do not get wet.

- The original authentic accessories must be purchased, and the use of other accessories can cause fatal damage to the machine.

- Check the instrument carefully before use, and check whether the glass flask is damaged or not, and whether the interfaces are consistent. Please handle with care.

These points are the basic knowledge of the maintenance of a rotary evaporator, and we should pay attention to frequent leak detection during use. Phenolphthalein test paper can be used for the leak, because ammonia is alkaline, and the phenolphthalein test paper turns red. When you look at it, the place where it is not frosted somewhere in the evaporator is the leak point. You can also find the leak with soapy water at the leak. Fluorescent evaporator leaks can be checked using halogen lamps and halogen leak detectors, or soapy water can be used to find leaks.

When inspecting, firstly use the eye to judge whether there is oil on the evaporation tube, because Freon and oil can be mutually soluble, and when Freon leaks, it will also seep out from the leak point. When using a halogen lamp to detect leaks, if there is a Freon leak, the flame of the halogen lamp will have a blue color, and the color will be slightly green, light green, grass green, purple green, purple, etc. to judge how much Freon leaks. If the flame is dark green or purple, the phosgene in the flame is toxic and cannot be checked by this method for a long time.

The above is the maintenance knowledge of a rotary evaporator we have summarized for you. We hope that the user will cherish the instrument during the use process and take care of it to ensure the normal working efficiency and service life of the instrument. In addition, if you want to know what the rotary evaporator brand is, please check our company website for more news.

What is the Function of Rotary Evaporator?

The rotary evaporation, or rotavap, is a common and essential equipment used for concentration, crystallization, drying, separation and solvent recovery in pharmaceutical,chemical and bio-pharmaceutical fields and other fields. Generally, it is used to remove a valtile solvent from a liquid mixture.

What is the Principle of Rotary Evaporator?

The principle is that the boiling points of liquids can reduce with the decreasing pressure. As a result, the solvents are capable of being vaporized at much lower temperature than their boiling points at the normal pressure.

[title text=”Related Products” tag_name=”h2″ color=”rgb(119, 199, 239)”]

[ux_products ids=”3028,56,123,131″]

[title text=”Related Posts” tag_name=”h2″ color=”rgb(119, 199, 239)”]

[blog_posts style=”vertical” columns=”3″ columns__md=”1″ depth=”2″ slider_nav_style=”simple” slider_nav_position=”outside” ids=”6326,4535,4339″ image_height=”89%” image_width=”43″]