Description

The equipment extracts essential oil and pure dew by distillation, applicable for the common and isolated distillation and extraction process of plant branches, leaves, flowers and grasses with high oil and fats content, animal materials with conventional oils and fats, and aromatic oil components. With an exquisite structure and simple operation, it’s especially suitable for the extraction of essential oil and pure dew in laboratories and at home.

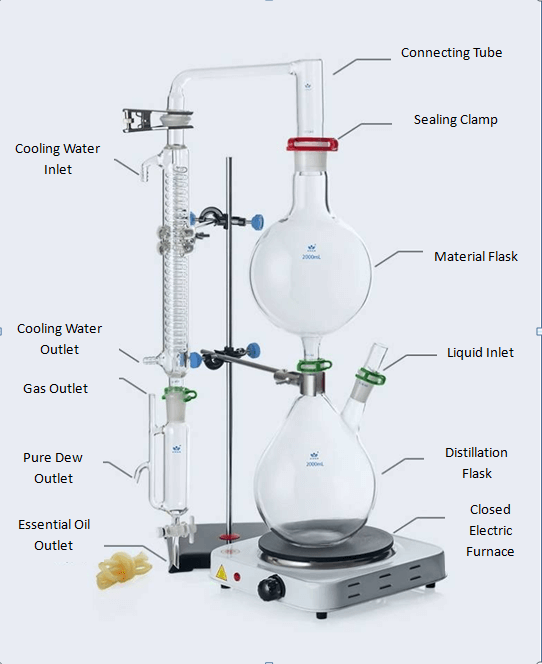

Product Parts

- Heat and high temperature resistance;

- Excellent sealing performance;

- High transparency;

- Solid material;

- Good corrosion resistance;

- Complete in specifications;

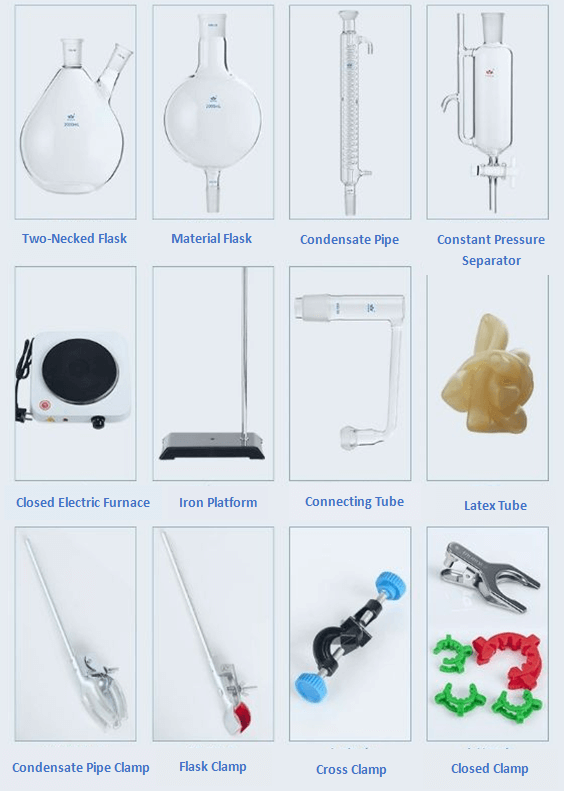

Product Accessories

A closed electric furnace, a distillation flask, a material flask, a connecting pipe, a condensate pipe, an oil-water separator(constant pressure separator), a iron platform, a sealing clamp, a laticifer

| Product Accessories List | |||

| Serial Number | Product Name | Specification | Quantity |

| 1 | Closed Electric Furnace | 220V/110V | 1 |

| 2 | Distillation Flask | 1L/2L | 1 |

| 3 | Material Flask | 1L/2L interface 40 24/40 | 1 |

| 4 | Connecting Pipe | 40 | 1 |

| 5 | Condensate Pipe | 24/40 | 1 |

| 6 | Constant Pressure Separator | 24/40 | 1 |

| 7 | Iron Platform | 1 | |

| 8 | Sealing Clamp | 4 | |

| 9 | Cross Clamp | 2 | |

| 10 | Flask Clamp | 1 | |

| 11 | Condensate Pipe Clamp | 1 | |

| 12 | Laticifer | 1m | 1 |

Application Methods

1. Place the electric furnace horizontally, and the iron platform next to the electric furnace. Install the flask clamp and cross clamp.

2. Place the two-necked flat bottom distillation flask on the center of the electric furnace and fill the flask with either water or ethanol. (With a low boiling point, the ethanol has a fast heating rate.)

3. Put the extract(It can be extracted as long as it contains essential oil) into the round bottom material flask. And the material flask is connected with the two-necked distillation flask, fixed with a flask clamp and a cross clamp.

4. Install the connecting pipe and the condensate pipe successively, tighten the grinding mouth and fix the condensate pipe with a flask clamp.

5. Install the separator and fix it with a plastic standard clamp.

6. Install a hose long enough on the water inlet and connect the other end to the faucet.

7. After the installation, check whether the instrument is fixed and clamps are fastened.

8. Turning on the electric furnace, it’s normal that the newly used electric furnace will fume, which smells like burnt plastic. Generally, it will be tasteless after heating for 20 minutes. Heat the two-necked flat bottom distillation flask until boiling. The steam will go through the material flask containing extracts, and will flow into the separator after being condensed by the condensate pipe. There will be more and more mixtures in the separator. For a small amount of mixtures, the valve can be opened to release the pure dew, leaving the top essential oil or releasing the essential oil after the distillation. For a large amount of mixtures, the extract can discharge spontaneously when mixtures reach the height of the dew outlet.

Application Methods of the Oil-Water Separator

According to the principle that oil is denser than water, the pure dew will flow out and the essential oil will be left. When reaching the upper branch, the essential oil can flow out from the left oil outlet. If the essential oil can’t reach the upper branch after finishing the distillation, what should be done is to close the valve after separating the pure dew. Then find another container and open the valve to make the essential oil discharge.

Precautions for Use

1. Before use, fix nuts well at the bottom of the iron platform, adjust the position of the cross and iron clamps, and connect the distillation flask with the material flask.

2. The water tank should be higher than the surface of the serpentine condensate pipe. With a syringe, inject about 30ml of water from the water inlet into the condensate pipe.

3. The water will flow out spontaneously when the latex tube is connected well and the water stop clip on the water outlet of the latex tube is loosened. (The Principle of Siphon Phenomenon)

4. The equipment isn’t applicable for the volatile oil with thermal instability.

Supplementary Information

Extraction Method of Rose Hydrosol:

1. Prepare 100g of rose petals and 200ml of water( If a higher concentration of the pure dew and a more intense aroma are needed, more rose petals can be added with less water.) Put rose petals into the material flask and add a little salt. Then shake the material flask so that it is evenly fused.

2. Open the closed electric furnace until water is heated into boiling and roses become lighter in color.

The distilled steam passes through the steam pipe into the serpentine condenser. With a oil-water separator, the pure dew will be separated.

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Reviews

There are no reviews yet.