Similarities and Differences between them

Both the rotary evaporator and the short path distillation are the equipment to extract or concentrate substances from mixtures, and both are high efficient and widely used in many fields. That is to say that the rotary evaporator and short path distillation have the same function. However, the rotary evaporator can only process one single material while short path distillation can process two or three materials. Besides that, there are still some comparisons and they are as follows:

1. In the short path distillation equipment, there is a short path transferring extracted materials from the evaporation flask to the condensing part, which may cause the extracted materials left at the short path easily. In this way, on the one hand, users need to clean the short path very often to guarantee the quality of experiment, which costs much time and money. On the other hand, the left extracted materials caused the waste of resource. In the rotary evaporator equipment, the extracted materials are transferred into condensing part directly with no distance, which prevents the waste of resource.

2. Because the cleaning requirements of laboratory glassware, users should clean them very frequently, in order to guarantee the quality of experiments. Therefore, the glassware in rotary evaporator equipment and short path distillation equipment should all be cleaned frequently.

3. Rotary evaporator and short path distillation are both used for the extraction of heat-sensitive substances. And they both are widely used in many fields, including people’s daily life at home, chemical, biochemical, make up and perfume, industrial and other fields.

How does a Rotary Evaporator Work?

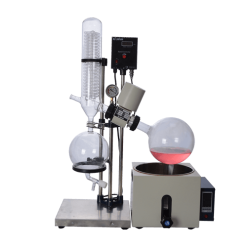

The rotary evaporation, or rotavap, is a common and essential equipment used for concentration, crystallization, drying, separation and solvent recovery in pharmaceutical,chemical and bio-pharmaceutical fields and other fields. Generally, it is used to remove a valtile solvent from a liquid mixture. A rotary evaporator mainly compose of following parts: a vacuum pump, a chiller, a condenser pump, a rotating flask and a receiving flask and other components. Most of people may be interested in a question how a rotary evaporator works. Hence, the working process of a rotary evaporator will be introduced specifically in the next section.

The working process of rotary evaporator is a consecutive process under a reduced environment. There are several steps for the operation:

a. Under reduced pressure, the evaporation flask was continuously rotated while the solvent was being distilled. The evaporation flask is a pear-shaped or round-bottomed flask with a standard ground mouth connection. It is connected with the pressure reduction pump through a serpentine condenser.

b. After substances get evaporated by heating, the gas-phase substances will go into condensing part to get condensed. In this step, gas substances are transferred through the glass tubes.

c. After gas-phase substances got condensed into liquid-phase, the liquid-phase substances will be transferred into receiving flask, which is the final destination of extracted substances. And then users will take the receiving flask out of rotary evaporator equipment.

During the whole working process, there is always a vacuum pump providing a vacuum environment for the rotary evaporator, which guarantees the whole system work in a reduced environment and the automatic feeding system formed by the pressure difference between atmosphere pressure and vacuum pressure.

How does a Short Path Distillation Work?

1. Molecules diffuse from the liquid phase to the evaporation surface:

The beginning of short path distillation’s working is from evaporation flask. Sample will be placed in the evaporation flask and be heated by heating mantle. The temperature that heating mantle provides can be adjusted according to the boiling points of different solvents.

2. Free evaporation of molecules on the liquid surface:

The evaporation speed of solvents can be changed by the heating temperature. Besides, the stability of sample solvents is also an important factor to influence the evaporation speed.

3. Molecules fly from the evaporation to the condensation surface:

The extracted gas-phase solvents will be transferred along a short distance, and be condensed along this distance. During this process, gas-phase solvents will be cooled down by the condensing part and turned into liquid-phase solvents.

4. Solvents will be collected in the receiving flask:

After gas-phase solvents being turned into liquid-phase solvents, it will be transferred into receiving flask and be collected efficiently. Collecting extracted solvents in the receiving flask is very convenient for users to get.

In the whole working process of short path distillation, there are always vacuum pump providing vacuum and condensing part turning gas-phase solvents into liquid-phase solvents.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/short-path-distillation-kit/2908.html

https://www.rotovap.cn/short-path-distillation-kit/2971.html

https://www.rotovap.cn/rotary-evaporator/6340.html

https://www.rotovap.cn/falling-film-evaporator-problems/3647.html