Product Description

A vortex trichome separator is a solventless separation device utilizing the mechanical separation technology to separate cannabinoids and terpene-rich trichome from biomass in order to produce high quality ice water hash.

Product Application

It is used for solventless extraction technology of hemp.

Product Advantages

- The solvent-free extraction can be performed.

- The countercurrent vortex can be generated.

- The interlayer can be connected to a chiller or a vacuum pump for thermal insulation, reducing the ice consumption.

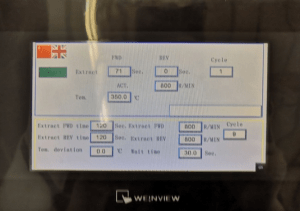

- The timing, forward rotation, reverse rotation, and other functions can be set.

- It is easy and convenient with the PLC control and one-button start.

- High efficient and productivity.

- The sink is made of food grade stainless steel, easy to clean.

- Set mobile wheels, convenient to change locations.

Product Parameters

| Product Name |

Vortex Trichome Separator |

|

| Model | TS-50 |

TS-75 |

|

Capacity |

190L |

285L |

|

Maximum Throughput |

14kg |

21kg |

|

Interlayer Volume |

30L |

|

|

Cooling Area |

0.9m2 |

|

|

Rotating Speed |

200-800rpm |

200-800rpm |

|

Power |

1.1KW |

1.1KW |

|

Measuring Range |

-20~100℃ |

-20~100℃ |

|

Material |

304 |

304 |

|

Overall Dimension |

1500*827*1360 |

|

|

Package Dimension |

990*920*1535 |

|

| Package Weight | 400kg | |

Working Principle

The bottom-driven blades combines with the uniquely shaped sink to generate a cross-flow turbulence, which develops a powerful stirring force. Without plant particulate pollution, the trichomes rapidly separate from the plant, remaining in water as suspended insoluble solids. It can be easily filtered, separated, collected and dried for obtaining high quality hash once the slurry mixture of water and trichomes has been separated from the remaining biomass.

Product Details

1.PLC control and one-button start.

3. The internal separation state can be clearly observed with a sight glass on the upper cover.

4. Set an overflow outlet. The water can be discharged from the overflow outlet when the seal leaks.

5. The mobile wheels are equipped, and both undirectional and universal wheels are used. It is convenient to change locations.

Accessory Products

- Chiller: DLSB 100L-10℃

- Stainless steel liquid storage tank: 100L

- Hash filter bag: eight layers

- Water pump: three tons

- Ice machine: the ice making capacity is 50kg

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.