Description

Principle of Wiped Film Distillation

Stainless steel wiped film molecular distillation, also known as short-path distillation, is a continuous distillation process carried out under high vacuum. The molecular distillation process is more precisely the process of molecular evaporation.

Molecular distillation is different from traditional distillation based on the separation principle of material boiling point difference. Molecular distillation is a special liquid-liquid separation technology that uses the principle of molecular free path to separate materials containing different substances.

Molecular distillation has the characteristics of short heating time, low distillation temperature and high degree of separation.

Molecular distillation is suitable for materials with high molecular weight, high boiling point, high viscosity, heat sensitivity and biological activity.

What is Stainless Steel Wiped Film Distillation Equipment?

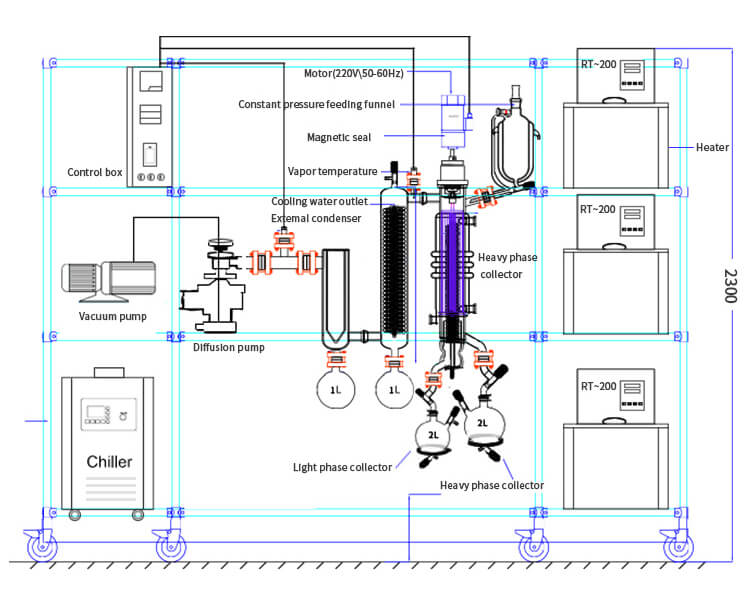

A complete set of molecular distillation equipment mainly includes: molecular evaporator, degassing system, feeding system, heating system, cooling vacuum system and control system. The molecular evaporator is the core part of the molecular distillation device.

Wiped-film molecular distillation equipment has high separation efficiency and has been widely used in fine chemicals, medicine, fragrances, essential oils, food and other industries. It has advanced technology, less risk of thermal decomposition, high productivity, and easy maintenance.

Features of Stainless Steel Wiped Film Distillation

Large heat transfer coefficient and high evaporation efficiency;

Stainless steel materials are safer, stronger, and not easily damaged;

Larger production scale and higher efficiency.

Advantages of Stainless Steel Wiped Film Distillation

Compared with conventional distillation, molecular distillation has the following advantages:

The operating temperature is low, which greatly saves energy consumption. Molecular distillation is operated far from the boiling point, so the energy consumption of the product is small.

The distillation pressure is low, and it is operated under high vacuum.

The heating time is short, reducing the heat damage of heat-sensitive substances. The decomposition or polymerization of substances is largely avoided.

Stainless steel molecular distillation separation degree and high product yield.

Structure Introduction

A complete set of molecular distillation equipment mainly includes: molecular evaporator, degassing system, feeding system, heating system, cooling vacuum system and control system.

Details of Stainless Steel Wiped Film Distillation Equipment

The gear pump is used for continuous feeding.

The gear pump is used for continuous discharg.

Jacketed conveying pipeline has good heat preservation effect.

The cooling system adopts serpentine condenser and cold trap.

The evaporator is made of high-quality stainless steel, which has fast heat transfer, high efficiency and durability.

Parameters of Stainless Steel Wiped Film Distillation

|

Stainless Steel Wiped Film Molecular Distillation |

||||||||||

|

Model |

FMD-0.1SS | FMD-0.15SS | FMD-0.25SS | FMD-0.35SS | FMD-0.5SS | FMD-1SS | FMD-1.5SS | FMD-2SS | FMD-3SS | FMD-5SS |

|

Effective evaporation area(m2) |

0.1 | 0.15 | 0.25 | 0.35 | 0.5 | 1 | 1.5 | 2 | 3 |

5 |

|

Condensing area(m2) |

0.17 | 0.3 | 0.4 | 0.7 | 1.7 | 2.7 | 3.5 | 4.9 | 6.5 |

8 |

|

Feeding speed(L/H) |

5-12 | 6-15 | 10-25 | 15-30 | 20-60 | 50-120 | 60-180 | 100-200 | 100-300 |

200-500 |

|

Rotate speed(r/min) |

30-350 | |||||||||

|

Stainless steel material |

304/316 |

|||||||||

|

Feeding method |

Gear pump automatic continuous feeding |

|||||||||

|

Discharge method |

Gear pump automatic continuous discharge |

|||||||||

|

Operating Temperature(℃) |

Within 350℃ |

|||||||||

| Voltage |

220V/60Hz Other voltages can be customized |

|||||||||

Application of Stainless Steel Wiped Film Distillation

Stainless Steel Wiped Film Distillation has been widely used in food, fine chemical engineering, chemical, grease daily chemical, synthetic resin, petrochemical.

After-sales Service

After-sales service principle:

Timely

Professional

Efficient

Cooperative

Certification

Packing and Shipping

Reviews

There are no reviews yet.