Basic constitution: The column cylinder is equipped with outside heating mantle, rotor and inside condenser. The fixing frame of rotor is precisely equipped with scratch film and anti-splash device. The inside condenser is placed in the center of evaporator, and the rotor should rotor between column cylinder and condenser.

Distillation process: The material should add from the top of evaporator and continuously spread to the heating surface through the material covered on rotor. Then, the scratch film is capable of scratching the material into a thin and flowing liquid film. During this process, the light molecular exceeded the heating surface form the condense liquid on inside condenser without any collision. Then, the molecular flows along the condenser tube, and discharge through the discharge tube on the bottom of evaporator. The residue liquid (heavy molecule) is collected on the circular channel under the heating zone, and flows through the discharge tube on one side.

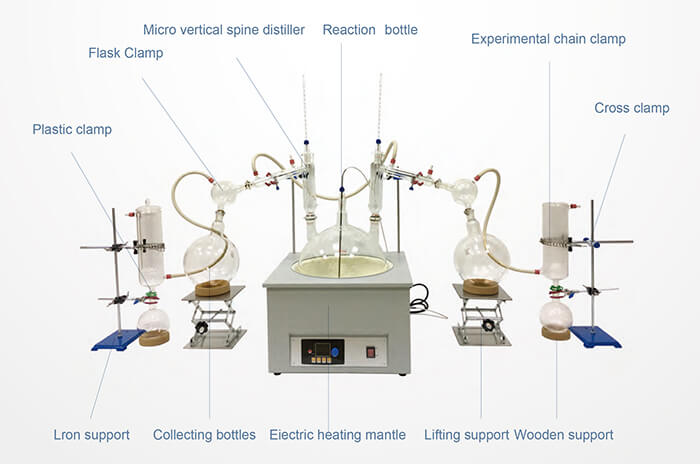

Product Details

Adopt three ports reaction bottle, with a special feeding port, which is convenient for feeding.

Micro vertical spine distiller, vertical spine structure, used for fractionation function; Vacuum sandwich is used to weaken the influence of wind and greenhouse, so as to maintain the appropriate temperature gradient in the column.

Vacuum valve can be equipped with the micro vertical spine distiller, used for vacuum pumping.

Glass parts are connected by frosted mouth, which is easy to operate and has good sealing. Plastic clip is fixed and avoid loose interface.

Product Parameters

| Short path distillation unit | ||||

| Model | SD-2 | SD-5 | SD-10 | SD-20 |

| Material | G3.3 | |||

| Heating Capacity(ml) | 2000 | 5000 | 10000 | 20000 |

| Heating temperature(℃) | Room temperature -250 | |||

| Accuracy(℃) | ±1 | |||

| Vaccuum Degree(Mpa) | 0.098 | |||

| Working temperature(℃) | 5-40 | |||

| Voltage | 220V/50Hzor110V/60Hz | 380V/50Hz | ||

| Package Size | 450*450*600 | 580*580*735 | 850*850*600 | |

| Weight | 18 | 24 | 30 | |