Product Description

R-1020 rotary evaporator’s rotary bottle maximum capacity is 20L, receiving bottle’s maximum capacity is 10L, rotate speed is 0-140r.p.m, and the motor power is 180W. RE-2002 rotary evaporator(evaporating bottle volume>10L) is equipped with double condenser(main and vice condenser), which has better condensation effect and higher recovery rate.

R-1020 rotary evaporator adopts stepless speed function to make rotary flask rotates in constant speed, the material formed a large area of thin film, then the constant temperature water bath begin to uniform heat the rotary flask and the material is evaporated in high speed under vacuum condition, the solvent steam is refrigerated by efficient glass condenser and received to receiving flask.

R-1020 rotary evaporator is a newly designed rotary evaporator of our company, this series has 5L, 6L, 10L, 20L, 50L for selection.

Product Advantages

R-1020 has new breakthroughs based on the RE-1002 rotary evaporator:

1. Equipped with PTFE valve between condenser and receiving flask, which has easy operation and good sealing.

2. Check valve control, continuous charging, available for vacuum switch in working condition. The check valve also could be replaced with hand-operated valve to convenient for operation, better sealing performance.

3. The discharging valve is made from teflon, consider of thermal expansion, other valves use glass valve element.

4. The water bath is electric lifting, lifting part use deceleration reinforcement motor, lifting process is more stable.

5. Use thicken rotary bottleneck to enhance loading bearing strength.

6. Use thicken rotary axis to enhance evaporation efficiency.

7. If the rotary evaporator sudden power lost during operation, when reconnect the power, it will automatic stop heating.

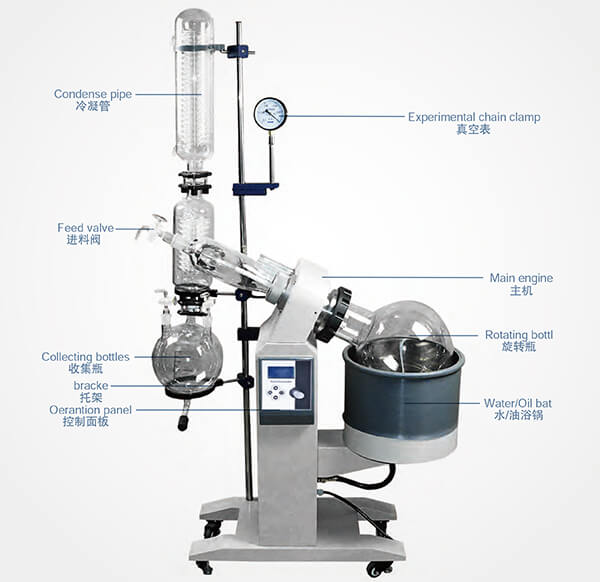

Product Parts

- The specially designed vacuum meter has high precision and good quality.

- LCD screen displays both temperature and rotating speed, and the operation is simple and convenient.

- Main condenser and auxiliary condenser structure, double backflow snakelike condenser increase cooling area and promote cooling efficiency.

- Flange connection makes it easy to dismount with high fastening strength.

Product Parameters

| Model | R-1005 | R-1010 | R-1020 | R-1050 |

|---|---|---|---|---|

| Optimum ambient temperature (℃) | 5~25 | |||

| Power (V/Hz) | Single-phase 110V/60HZ | Single-phase 220V/60HZ | ||

| Speed regulation of main engine | Digital variable-frequency stepless speed regulation | Digital direct current stepless speed regulation | ||

| Rotate speed of main engine (rpm) | 10-140 | 20-130 | 20-110 | |

| Rotary motor | 40 | 60 | 120 | |

| Temperature control (℃) | Digital temperature control, constant temperature -99℃ | |||

| Maximum vacuum degree (Pa) | 399.9Pa(under 3mmHg) | |||

| Rotary flask (L) | 5 Flange mouthØ50 | 10 Flange mouthØ95 | 20 Flange mouthØ125 | 50 Flange mouth Ø125 |

| Receiving flask (L) | 3 | 5 | 10 | 20 |

| Condenser pipe | Vertical dual coil pipe | Upright, main condenser + auxiliary condenser, efficient tri-backflow condenser pipe | ||

| Evaporative capacity (L/h) | Water ≥2 Alcohol ≥4 | Water ≥3.2 Alcohol ≥6.5 | Water ≥5 Alcohol ≥11 | Water ≥9 Alcohol ≥19 |

| Water bath pot material | Stainless steel | |||

| Water bath pot size (mm) | Φ280×170 | Φ350×220 | Φ450×250 | Φ550×320 |

| Lifting function | Electric lifting | Electric + manual lifting | ||

| Lifting stroke (mm) | 0-150 | 0-160 | 0-190 | 0-180 |

| Complete machine power (kW) | 2.2 | 4.8 | 6.3 | 8.3 |

| Dimension (mm) | 765×400×1070 | 920×550×1700 | 1250×600×2100 | 1320×770×2340 |

Packing List

| Host | 1 | Rotary Bottle | 1 |

| Electric Cabinet | 1 | Recycling bottle | 1 |

| Aluminum Backing Ring of Special Sealing Ring | 1 | Evaporator Condenser Pipe | 1 |

| Sealing Gasket | 1 | Suction Pipe | 1 |

| Protective Pipe 3A | 1 | Protective Pipe | 1 |

| Thermostat Water Bath Kettle | 1 | Special Components (additional purchase) |

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.