Description

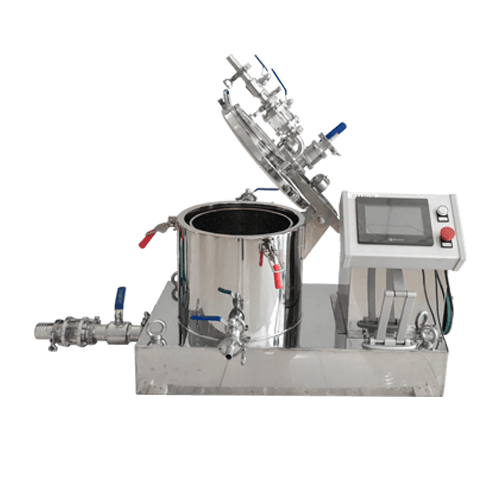

The industrial centrifuge is a filtering device with bottom scraper discharging and intermittent operation, raw materials is added to the rotary drum from the top, under the action of centrifugal force field, liquid phase will discharge outside the machine through filter medium, and the solid phase is trapped in the drum. After the drum is decelerated, solid phase will be scraped off by the scraper and discharged from the bottom of the centrifuge. It has the characteristics of stable operation and convenient operation.

PP series centrifuges are specially designed for plant extraction, with airtight, explosion-proof and clean functions. The PP series centrifuge adopts a flat-bottomed drum structure.

Larger volume, higher cleanliness, non-polluting structure design, easy operation, clean appearance, stable and excellent performance are favored by consumers.

Principle

Fill the filter bag with crushed plant material and place it in the machine.

Then, add alcohol until the plant material is submerged, and set the program to rotate in both directions to fully extract the active ingredients in the plant.

Open the bottom valve to release the extract, and the plant material is dried at high speed to remove as much liquid as possible.

Parameters

| Model | Diameter (mm) | Separating Factor | Rotary Drum Height mm | Volume

L |

Rotary Speed r/min | Motor Power KW | Dimension mm | Gross Weight KG |

| PP-15 | 300 | 430 | 250 | 15 | 2000 | 1.1 | 1100*650*1020 | 240 |

| PP-25 | 300 | 430 | 350 | 25 | 2000 | 1.5 | 1100*650*1020 | 260 |

| PP-45 | 450 | 400 | 300 | 45 | 1500 | 2.2 | 1400*850*1080 | 380 |

| PP-60 | 450 | 400 | 400 | 65 | 1500 | 3 | 1400*850*1080 | 410 |

| PP-110 | 600 | 540 | 400 | 115 | 1250 | 4 | 1600*1060*1250 | 800 |

| PP-140 | 600 | 540 | 500 | 145 | 1250 | 5.5 | 1600*1060*1330 | 820 |

| PP-250 | 800 | 560 | 500 | 250 | 1100 | 11 | 1700*1400*1600 | 1350 |

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Reviews

There are no reviews yet.