Freeze-drying is a technique for drying by the principle of sublimation, which is to quickly freeze the dried material at low temperature. Then the frozen water molecules are directly sublimated into a process of water vapor evolution in a proper vacuum environment. The product of this process is called Freeze-dried product.

Product Features

1.Dry chamber door and cold well door adopt aviation acrylic materials with high strength and no leakage.

2.Seven-inch true color industrial touch screen has high control precision, stable performance, and is easy to operate.

3.Internationally famous brand compressors are efficient in energy and more stable.

4.Inflate valve, drain valve and high vacuum safety diaphragm valve can be connected with inert gas, which can extend material shelf life.

5.Manual, automatic model for choice, manual mode for exploring the process; automatic mode for mature technology, one button operating.

6.Monitoring screen; real-time monitoring of plate temperature, cold trap temperature, vacuum and other operating conditions.

7.Data record mode, data record multiple selection, data export and other functions.

8.Two temperature control modes can be switched at any time; standard temperature rise and fall mode, with smooth temperature control mode.

9.Freeze-drying curve query function, so you can view the temperature, vacuum and other curves at any time.

10.Set user level and permissions password, so users can enter into the manager system based on the permissions.

11.This machine can store 40 sets of freeze-drying process, each set can set 36 segments.

12.The machine use 36V electric defrost, compare with non-electric defrost, the speed is faster and the safety grade is higher.

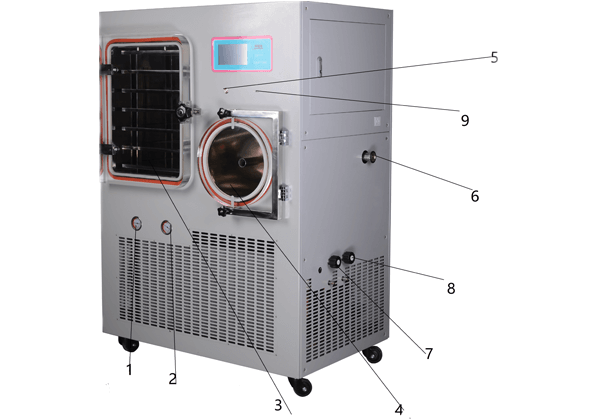

Product Structure

1.First-stage high pressure gauge

2.Second-stage high pressure gauge

3.The door of drying room

4.The door of cold trap

5.Main switch

6.Vacuum interface

7.Water drain valve

8.Inflation valve

9.USB interface

Product Parameters

| Classical type | ZLGJ-20 | ZLGJ-30 | ZLGJ-50 | ZLGJ-100 |

| Freeze-dried area | 0.3M2 | 0.4M2 | 0.5M2 | 1M2 |

| Number of plate | 3+1 | 3+1 | 4+1 | 6+1 |

| Plates space | 50mm | 50mm | 50mm | 70mm |

| Plate size | 270*400*15 | 300*340*15 | 360*480*15 | 360*480*15 |

| Plate temperature | -50℃ to 70℃ | -50℃ to 70℃ | -50℃ to 70℃ | -50℃ to 70℃ |

| Cold trap temperature | ≤-75℃ | ≤-75℃ | ≤-75℃ | ≤-75℃ |

| Water for cold trap | 4KG/24Hr | 6KG/24Hr | 8KG/24Hr | 15KG/24Hr |

| Defrost | 36V electric defrost | Natural defrost | Natural defrost | 36V electric defrost |

| Voltage | AC220V/50Hz | AC220V/50Hz | AC220V/50Hz AC380V/50Hz |

AC380V/50Hz |

| Dimension | 800*800*1550 | 880*735*1320 | 960*785*1450 | 1020*780*1700 |

Packing and Delivery

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.