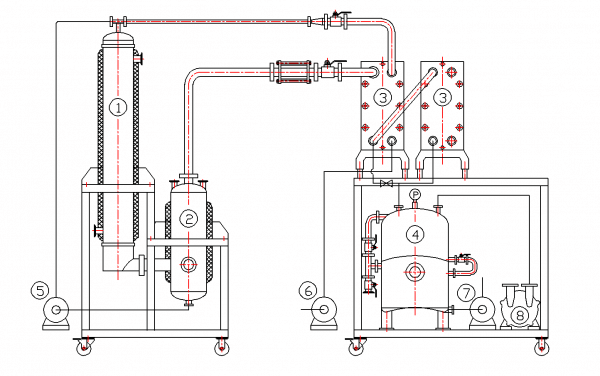

Product Introduction

①Tubular Heat Exchanger ②Gas-Liquid Separation Chamber

③Plate Heat Exchanger ④Liquid Storage Tank

⑤Discharge Pump for Concentration Liquid ⑥Feed Pump

⑦Discharge Pump for Solvent ⑧Water Circulating Vacuum Pump

Product Parameters

| Model | FFE-100L | FFE-200L | FFE-500L | FFE-1000L |

| Evaporation Rate (L/hr) | 100 | 200 | 500 | 1000 |

| Evaporator Part Dimension (W*D*H cm) | 95*85*250 | 110*90*260 | 120*100*300 | 140*120*300 |

| Condenser Part Dimension (W*D*H cm) | 120*85*250 | 130*90*250 | 130*100*250 | 130*120*250 |

| Feeding Pump (kw) | 0.37 | 0.37 | 0.37 | 0.75 |

| Discharge Pump (Oil, kw) | 0.75 | 0.75 | 0.75 | 0.75 |

| Discharge Pump (Ethanol, kw) | 0.75 | 0.75 | 0.75 | 0.75 |

| Panel (kw) | <50 | <50 | <50 | <50 |

| Total Weight (kg) | 1000 | 1300 | 1500 | 1800 |

| Total Power (kw) | 4 | 4 | 6.5 | 6.5 |

| Electricity | 240V, 3 Phase, 60Hz or Customizable | |||

Product Details

1. The sight glass is used for observing the evaporation process.

2. The anti-explosion control cabinet is safe without spark.

3. Sanitary 304 stainless steel pipe fittings 9 is wonderful.

4. The elaborately made distributor and tubular heat exchanger are quite suitable for heating evenly.

Quality Certification

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.