Description

Product Introduction

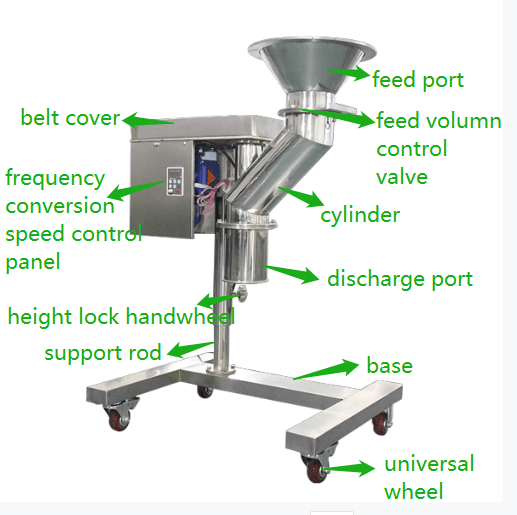

The fast granulator is suitable for crushing and finishing granules in Chinese and Western medicine, food, chemical pigment, feed and other industries. This machine is generally used with granulation dryer. The materials with different particle shapes and specifications obtained by various granulating dryers are cut by the high-speed rotating blades of this machine, and discharged through the steel plate, then the granules with the same shape and specifications can be obtained.

Product Usage

(1) Used for dry, fragile, and non-hard materials;

(2) Used for wet, fragile, and non-hard materials;

(3) Used for hard materials or uneven materials, accompanied by crushing effect;

Working Principle

After the material from the granulating dryer enters the feed port of the granulator, it falls into the cylindrical working room. The rotating rotary knife acts on the material to swirl, and the particles are thrown to the screen surface by centrifugal force. At the same time, the high-speed rotation of the rotary knife has a shearing effect on the screen surface, The particles are crushed into small particles between the rotary knife and the screen and discharged through the screen.

Granule size of granulator:

- Number of screens

- The distance between the rotary knife and the screen

- The speed of the rotary knife speed

Product Parameters

| Model | KZL-80 | KZL-120 | KZL-160 | KZL-180 |

| Screen diameter(mm) | 80 | 120 | 160 | 180 |

| Production capacity(kg/h) | 50-200 | 100-300 | 150-400 | 200-500 |

| Motor power(kw) | 0.75 | 1.1 | 1.5 | 1.5 |

| Speed(r/min) | 0-1440(adjustable) | 0-1440(adjustable) | 0-1440 (adjustable) | 0-1440(adjustable) |

| Dimensions(mm) | 630×430×900 | 800×600×950 | 800×600×1050 | 930×650×1200 |

| Weight(mm) | 90 | 110 | 120 | 150 |

| Price(yuan) | 7500 | 8000 | 9000 | 10000 |

Product Advantages

- Low energy consumption. The rare earth permanent magnet variable frequency motor is used, which is in a dormant state when not in use, and saves about 30%-50% of electricity compared with similar products.

- Control technology. The motor speed can be automatically adjusted according to the customer’s air consumption, and the user can view or control it remotely, truly unattended at the operation site.

- The efficiency is increased by more than 30%. The compression efficiency is high, and the transmission efficiency is high. Compared with similar products, the efficiency is increased by more than 30%.

- The noise during operation is lower than 50 decibels. Users making calls in their vicinity will not be affected and can be installed directly at the production site without noise pollution.

Product Details

- The hand wheel can be adjusted up and down, the height can be customized to adjust and can be fixed with good practicality.

the hand wheel

- The control panel is easy to operate and can be frequency-converted to adjust speed.

control panel

- The universal wheel is easy to move and can be used in a variety of places.

universal wheel

- The I-shaped base is convenient for placing the receiving container and reduces the waste of operating space.

I-shaped base

Reviews

There are no reviews yet.