Description

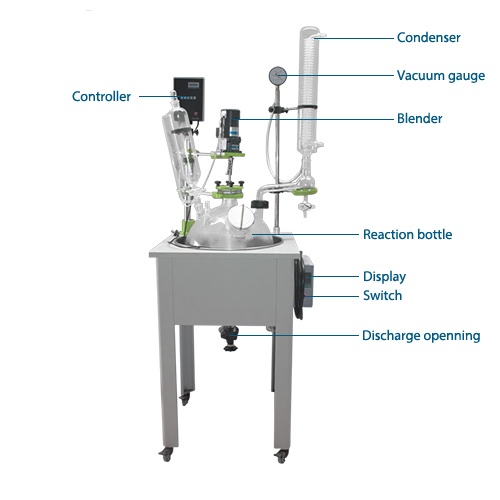

F-50L single layer glass reactor is a series product of single layer glass reactor, its max volume is 50L, max rotating speed can reach to 450rpm, its reaction bottle volume is 50L, that’s why it is known as F-50L single layer glass reactor, also called: glass vacuum reactor, extractor, multifunctional reactors, it can make various of solvent synthesis reaction under the condition of constant temperature.

Product Details

.jpg)

Product Parameters

| Basic parameter |

Model | Single layer glass reactor |

| Volume of the reactor bottle | 50L | |

| Glass material | GG-17 | |

| Spraying plastic anti-corrosion shell size(mm) | 740*640*960 | |

| Stainless steel container size(mm) | 550*320 | |

| Movement method | Universal castor with brake | |

| Reaction bottle number | Spherical shape 7 pieces | |

| Lifting of discharging port | 450mm | |

| Reaction temperature | -80-250℃ | |

| Vacuum degree | 0.098Mpa | |

| Stirring speed | 0-450rpm | |

| Stirring shaft diameter | 15mm | |

| Stirring power | 120W 1/3 | |

| Heating power | 8KW | |

| Overall dimension(mm) | 800*640*2200 | |

| Packing dimension(mm) | 1440*720*890 | |

| Package weight(KG) | 90 | |

| Function device |

Electrical machine | Low speed reinforcement electric machine, speed rate 3: 1 |

| Rotating speed display mode | Liquid crystal digital display | |

| Pot temperature display mode | Digital display | |

| PTFE sealing | ¢70 Flange stirring port | |

| Condenser | 120*600mm | |

| Backflow(distillation) device | Backflow elbow with discharging switch, 50# ground port | |

| Drop device | 2L/34 standard port | |

| Pressure reduce device | 34# standard port pressure reduce valve | |

| Temperature measuring tube | 24# standard port | |

| Solid discharge(washing) port | ¢120 flange port with PTFE cover | |

| Discharging method | Inclined discharging glass valve, ¢80 flange port | |

| Vacuum display method | Vacuum meter | |

| Stirring connection method | Universal joint connection | |

| Stirring rod | Anchor type stainless steel rod, covered with PTFE | |

| Optional device |

Shell | 304 stainless steel |

| Collecting device | Collection bottle | |

| Cooling circulating device | Cooling cooper coil tube | |

| Explosion-proof | Explosion-proof inverter/Explosion proof motors 180W/370W 0-1400rmp | |

| Main body | Spraying PTFE of whole instrument | |

| Heating device | electric heating jacket heating | |

| Our laboratory equipment can be customized according to customers actual needs. | ||

Packing and Delivery

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Reviews

There are no reviews yet.