Description

Product Description

The craft beer brewing equipment is specially designed for fine brewing of beer, varying from traditional large beer and home-brewed equipment. Simply speaking, it can utilize more and better ingredients to brew high quality and high concentration beer. Crucially, each craft brewery can add various flavorings such as chocolate, coffee, fruit and even wood. Therefore, the craft beer is highly creative with a great variety of flavors.

The craft beer brewing equipment is primarily designed for hotels, bars, nightclubs, manors and like places. Under the background that the mass beer has gradually saturated, the high-end product tends to develop rapidly in the beer market in China. The craft beer grows significantly along with the craft beer market being favored by more and more people.

Brewing Process

- Malt milling: Crush malt with a grinder.

- Mashing: Put the crushed malt into a mash tun and boil them to extract the sugar in the malt.

- Filtration: Do solid-liquid separation for mash to obtain clear wort.

- Fermentation: Pour the wort into a fermentation tank and ferment with yeast.

Product Configuration

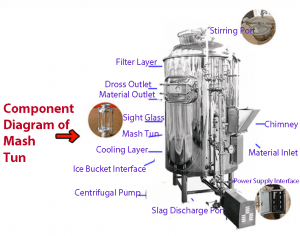

- Mashing system: saccharification and filtration integrated tun (The capacity of the mash and boil tun is 500l, and the capacity of the filtration and spiral decanting tun is 500l)

- Fermenting system: four 500l fermentation tanks (Optional)

- Crushing system: one malt grinder

①Malt grinder

②Mashing system

③Fermenting system

④Cooling system

⑤Other accessory products

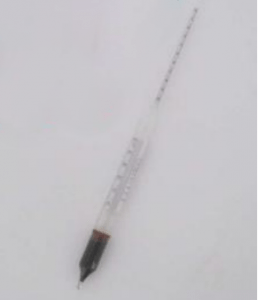

Temperature Saccharometer (Mercury Type)

The main sugar ranges: 0-10, 10-20, 20-30, 0-15, 0-20

Length: 38/39cm

Thermometer range: 0-50℃

Product Features

- The craft beer brewing equipment can be made of copper plate, rose gold plate, black titanium plate and stainless steel, which is gorgeous and elegant.

- It can brew nearly 20 kinds of beers with various tastes, such as stout, bright beer, catrina, fruit beer, and kwas chlebowy.

- It is easy and flexible to operate with low power consumption and small occupied area.

- The production environment is clean without pollution, and the bouquet is overflowing.

- With a high degree of automation, the non-professional brewing people can also brew the best beer.

Differences Between Craft Beer and Regular Beer

Different raw materials.

- Craft Beer:It is brewed using malt, hops, yeast and water without any artificial additives. Normally, the craft beer is brewed without much consideration of cost. Most craft beer is brewed with high quality raw material with a variety of tastes and flavors, which can be changed according to one’s own taste.

- Regular Beer: It is also brewed using malt, hops, yeast and water. But the malt is mostly replaced by rice, corn, starch and other raw materials in order to reduce the cost. The brewed beer is quite low in concentration of wort and light in taste. Both the alcohol degree and the malt content are relatively low. Some beer is brewed with syrup, and the malt essence is directly added to give the beer a malt flavor.

Different fermentation technology.

- Craft Beer: The craft beer is mostly Ale. The yeast works at the top of fermentation tanks, floating above the liquor. The fermentation temperature is generally controlled at 8-12℃. The craft beer is kept and refrigerated at a low temperature of 2-4℃after completing the fermentation. The fermentation tanks are usually small, and the craft beer requires no filtration and sterilization after the fermentation.

- Regular Beer: the regular beer is mostly Lager. The yeast works at the bottom of fermentation tanks, sinking beneath the liquor. The fermentation temperature is normally controlled under 10℃. The fermentation tanks are relatively large, and the regular beer usually adopts the filtration and pasteurization to lengthen the shelf life.

Different fermentation time.

- Craft Beer: Caring less about the cost, the fermentation time is often not particularly important. The most traditional craft beer can be fermented for up to two months, which gives the beer a full fermentation, a higher wort concentration and a stronger flavor.

- Regular Beer: Time is money for industrial beer. Thus the fermentation time is normally about seven days. The fermentation is not particularly full, leading to a lower wort concentration and lighter flavor.

Product Parameters

500L Mashing System

| No. | Name | Modle | Quantity | Material | Technical Parameter | |

| Mashing System | 1 | Boil and Whirlpool Tun (Substratum) | 500L | One set | Stainless steel | 1. Overall Dimension: φ1100×2200; 2. Total Volume: the design volume is 600l, and the effective volume is 500l; 3. Internal Container: stainless steel 304. The thickness is 2mm. 4. External Cover: stainless steel 201. The thickness is 1.5mm. 5. Heating Mode: electric heating. The heating area is 1.18㎡, and the heating power is 24kw. 6. Interlayer: stainless steel 304. The thickness is 2mm. 7. Hypocone: stainless steel 304. The thickness is 2mm. The cone base is 160 degrees. 8. Insulating Layer Thickness: 80mm; polyurethane foam. 9. Welding Manner: argon shielded welding. 10. Temperature Measuring Mode: equipped with PT100 intelligent temperature measurement probe with centralized display control. 11. Feed and Discharge Mode: the pump is ued for feeding and discharging with the feed buckle whose length is 450mm and width is 330mm. 12. Stirring Method: water flow agitation. 13. Landing Legs: four stainless steel landing legs. |

| 2 | Filter and Temporary Storage Tank (Superstratum) |

500L | One set | Stainless steel | 1. Total Volume: the design volume is 700l, and the effective volume is 500l; 2. Internal Container: stainless steel 304. The thickness is 2mm. 3. External Cover: stainless steel 304. The thickness is 1.5mm. 4. Steam Interlayer: stainless steel 304. The thickness is 3mm. 5. Hypocone: stainless steel 304. The thickness is 3mm. The cone base is 160 degrees. 6. Insulating Layer Thickness: 80mm; polyurethane foam. 7. Filter Sieve Plate: stainless steel sieve plate. The distance between each is 0.8mm, and it can be dismounted. 8. Welding Manner: argon shielded welding. 9. Feed and Discharge Mode: the pump is ued for feeding and discharging. 10. Tank Top: equipped with Ф350 layering normal pressure manhole. Stainless steel 304. 11. Filtering Method: gravity sedimentation filtration. 12. Dross Discharge Mode: dry dross discharge. It is equipped with a dross discharge door whose length is 450mm and width is 330mm. |

|

| 3 | Malt Grinder | XW-BXG-200-H2 Type | One unit | Roller, motor, pulley, belt matching. 200KG/H, 380V. Motor Power: 0.75KW | ||

| 4 | Circulating Water Pump | Rate of Flow: 3m³/h | One unit | Stainless steel | The sanitary stainless steel beverage pump is matched with the whole mashing system. Power: 0.75KW | |

| Accessory Device of Mashing System | 5 | Honeycomb Briquette Type Condenser | BR0.05/4- 12 | One unit | Stainless steel | Dual-stage cooling. Heat exchange area: 5㎡ |

| 6 | Combined Pipelines for Mashing | ISO:Φ40/Φ32 | One unit | Stainless steel | Food grade sanitary stainless steel valves and pipelines | |

| 7 | Wort Thermometer | 0~150℃ | Two pieces | Glass / Stainless steel | Thermometers with stainless steel metal sleeves | |

| Fermenting System | 8 | Fermentation Tank | 500L | Stainless steel | 1. Overall Dimension: Ф1000*1000*2200 2. Total Volume: 600L, Effective Volume: 500L 3. Control Mode: Each tank can be controlled individually. The coiled jacket is used for cooling. 4. Internal Container: stainless steel 304 5. External Cover: stainless steel 304 6. Heat exchange area: 2.3㎡ 7. Hypocone: stainless steel 304. The thickness is 3mm. The cone base is 160 degrees. 8. Insulating Layer Thickness: 80mm; polyurethane foam. 9. Welding Manner: argon shielded welding. 10. Temperature Measuring Mode: equipped with PT100 intelligent temperature measurement probe with centralized display control. 11. Feed Mode: feed from the bottom of the yeast 12. Discharge Mode: the bottom is designed with two pipelines, and the beer discharge pipe is higher than the drain outlet. Note: equipped with the dry feed port for hops |

|

| Spare Parts | 01 | Quick Fitting Leather Hose Joint | Ф32 | Eight pieces | Stainless steel | Beverage pump accessories |

| 02 | Clamp Butterfly Bamper Rubber Pad | Ф32 | 20 pieces | Silica gel | ||

| 03 | Butterfly Bamper | Ф32 | One piece | Stainless steel | They are connected by clamps. | |

| 04 | Clamp | Ф32 | Five piece | Stainless steel | ||

| 05 | Special Tools | / | One set | / | The non-standard tools are specially used for the device. | |

Product Details

- The circulating water pump is made of stainless steel, satisfying the state sanitary standards.

- The reflux valve is made of stainless steel and brass, which is safe, sanitary and anti-corrosion.

- The sight glass is made of toughened organic glass, with a high transparency.

FAQ

- How does the craft beer taste?

A: The taste is intense with malt flavors. The intensity and colors can be adjusted.

- What raw materials are required for brewing beer?

A: The barley malt, hops, yeast and other raw material are required. We can provide nearly 20 beer brewing formulas for customers.

- What kind of beer can be brewed?

A: It can brew a great variety of beers, such as bright beer, stout, wheat beer, catrina and fruit beer.

- What kind of technical support can you provide?

A: Our company can provide installation videos, and even install and debug the device on site when necessary. We can also provide beer brewing formulas for ever.

- Is the beer safe and healthful?

A: All products in our company are made of food grade stainless steel, which is green and healthful without contamination.

- Is the device require a large occupation area? Is it easy to operate?

A: As an integrated device, the product consists of a mash tun and four fermentation tanks, featuring small occupation area, simple operation and low cost.

- What kind of payment terms do you accept?

A: Normally we accept TT, Paypal, Western Union, Alibaba Escrow, and L/C. The specific term will be discussed during the deal.

- How do you package product?

A: The tiny pieces are packed by special cartons, and the large piece are packed by non-fumigation wooden boxes.

Relevant Recommendation

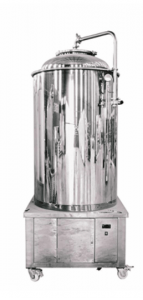

With a great variety of fermentation tanks, the customer can choose based on their own needs.

| Flange Type Fermentation Tank | |

| Product Model | 500L Beer Fermentation Tank (Flange Type) |

| Product Capacity | 500L |

| Device Thickness | 2.0-3.0mm |

| Device Material | Food Grade Stainless Steel 304 |

| Device Dimension | 0.95*0.95*2.1m (length*width*height) |

| Service Power | 300W |

| Service Voltage | 220V |

| Cleaning System | CIP Cleaning System |

| Occupation Area | About 1㎡ |

| The fermentation system is mobile with universal wheels, and all tanks adopt an individual compressor, convenient to move during operation. | |

| A great variety of beers can be made: Bright beer, stout, wheat beer, catrina, weissbier, pineapple beer, warm beer, osmanthus beer. | |

| Board Type Fermentation Tank | |

| Product Model | 500L Beer Fermentation Tank (Board Type) |

| Product Capacity | 500L |

| Device Thickness | 2.0-3.0mm |

| Device Material | Food Grade Stainless Steel 304 |

| Device Dimension | 0.95*0.95*2.3m (length*width*height) |

| Service Power | 300W |

| Service Voltage | 220V |

| Cleaning System | CIP Cleaning System |

| Occupation Area | About 1m2 |

| The fermentation system is mobile with universal wheels, and all tanks adopt an individual compressor, convenient to move during operation. | |

| A great variety of beers can be made: Bright beer, stout, wheat beer, catrina, weissbier, pineapple beer, warm beer, osmanthus beer. | |

| Barrel Type Fermentation Tank | |

| Product Model | 500L Beer Fermentation Tank (Barrel Type) |

| Product Capacity | 500L |

| Device Thickness | 2.0-3.0mm |

| Device Material | Food Grade Stainless Steel 304 |

| Device Dimension | 0.95*0.95*2.25m (length*width*height) |

| Service Power | 300W |

| Service Voltage | 220V |

| Cleaning System | CIP Cleaning System |

| Occupation Area | About 1m2 |

| The fermentation system is mobile with universal wheels, and all tanks adopt an individual compressor, convenient to move during operation. | |

| A great variety of beers can be made: Bright beer, stout, wheat beer, catrina, weissbier, pineapple beer, warm beer, osmanthus beer. | |

| Manhole Type Fermentation Tank | |

| Product Model | 500L Beer Fermentation Tank (Manhole Type) |

| Product Capacity | 500L |

| Device Thickness | 2.0-3.0mm |

| Device Material | Food Grade Stainless Steel 304 |

| Device Dimension | 0.95*0.95*2.3m (length*width*height) |

| Service Power | 300W |

| Service Voltage | 220V |

| Cleaning System | CIP Cleaning System |

| Occupation Area | About 1m2 |

| The fermentation system is mobile with universal wheels, and all tanks adopt an individual compressor, convenient to move during operation. | |

| A great variety of beers can be made: Bright beer, stout, wheat beer, catrina, weissbier, pineapple beer, warm beer, osmanthus beer. | |

Accessory Products

1.Beer Mug Cleaning Machine

2.Can Filling Machine

After-Sales Service

Pre-Sale Service

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide detailed product performance specification;

- Provide professional quotation information;

- Provide 24-hour technical consultation and reply;

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard;

After-Sale Service

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied.

Packing and Shipping

[title style=”center” text=”Send Message” color=”rgba(32, 163, 219, 0.81)”]

Error: Contact form not found.

Reviews

There are no reviews yet.