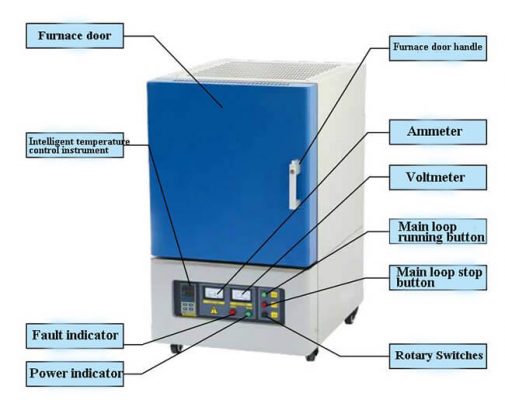

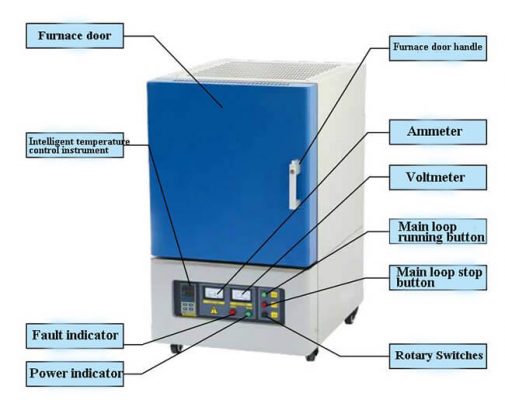

Description

SA2 series box-type atmosphere furnace is a special furnace designed for products that require atmosphere protection. The furnace chamber can be filled with inert gas, nitrogen, also can be pumped out with vacuum, so that the workpiece will not produce oxidative decarburization. It is suitable for atmosphere protection sintering and atmosphere reduction in industrial and mining enterprises. The atmosphere furnace is equipped with various valves, flow meters, pressure gauges, etc. as required. The furnace body has good airtightness, the vacuum degree can reach -0.1MPa, the operation is simple, and the loading and unloading is convenient.

Product Application

The box-type atmosphere furnace is suitable for various colleges and universities laboratories, industrial and mining enterprise laboratories, for chemical analysis, physical determination, as well as for the sintering and melting of metals and ceramics, and for heating, roasting, drying, and heat treatment of small steel parts.

Product Advantages

SA2 series (1200℃ /1400℃ /1700℃ /1800℃) atmosphere furnace has the following advantages:

- 30-segment intelligent temperature control regulator, PID control, temperature control accuracy ±1 degree.

- Inert gas, nitrogen, etc. can be introduced into the furnace.

- The temperature upper limit alarm can be set, and the main circuit can be automatically cut off when the temperature exceeds the upper limit.

- Using high-purity alumina ceramic fiber as the furnace material, and the heat preservation effect is good.

- Different furnace chamber sizes can be customized according to customer requirements.

- The furnace door is sealed with silica gel, and the four corners of the furnace door are locked with locks, and the sealing performance is good.

Product Parameters

| Item No. | Max. Temperature | Inner Chamber size (D*W*H) (mm) | Voltage/Power (V/KW) |

| SA2-1-12TP | 1200℃ | 100*100*100 | AC 220V/1KW |

| SA2-2-12TP | 1200℃ | 200*150*150 | AC 220V/2KW |

| SA2-6-12TP | 1200℃ | 300*200*200 | AC 220V/6KW |

| SA2-9-12TP | 1200℃ | 400*300*300 | AC 380V/9KW |

| SA2-2-14TP | 1400℃ | 100*100*100 | AC 220V/2KW |

| SA2-4-14TP | 1400℃ | 200*150*150 | AC 220V/4KW |

| SA2-7-14TP | 1400℃ | 300*200*200 | AC 220V/7KW |

| SA2-16-14TP | 1400℃ | 400*300*300 | AC 380V/16KW |

| SA2-2-17TP | 1700℃ | 100*100*100 | AC 220V/2KW |

| SA2-4-17TP | 1700℃ | 200*150*150 | AC 220V/4KW |

| SA2-9-17TP | 1700℃ | 300*200*200 | AC 380V/9KW |

| SA2-16-17TP | 1700℃ | 400*300*300 | AC 380V/16KW |

Matters Needing Attention

- Do not place it on an uneven or vibrating site, otherwise it will easily cause the equipment to be unstable and tip over.

- Do not put flammable and explosive materials near the furnace body, otherwise there is a danger of explosion.

- Do not drop screws, gaskets and other metal objects into the equipment, otherwise it may cause a short circuit or fire in the equipment.

- Do not place it in a place where water is easy to splash. If water enters the product body, it may cause fire and electric shock.

- The equipment should be installed in an environment where there is no conductive, dust-free, and non-damaging gas or steam.

- The place of placement should be a place with air circulation, no vibration, no impact, and no high dust.

- The wiring work must be carried out by qualified personnel, otherwise there is a danger of electric shock.

- Make sure that the input power is completely disconnected before wiring work, otherwise there is a danger of electric shock.

- The equipment must be reliably grounded when it is connected to the power source, otherwise there is a danger of electric shock.

- Do not drop metal objects such as screws, gaskets, etc. into the inside of the equipment, otherwise it may cause a short circuit or fire hazard in the equipment.

- The equipment power supply must be connected to the corresponding air switch.

Operating Requirments

1 If the atmosphere furnace is used for the first time or if it is not used for a long time, it should be used after baking at about 300℃ for 2 hours to avoid cracking of the furnace chamber.

2 Furnace temperature should not exceed the rated temperature, so as not to damage the heating element and the furnace chamber. It is forbidden to directly pour liquid or molten metal into the furnace. Frequently remove the metal and oxidation residues in the furnace chamber to keep the chamber clean.

3 Please lock the furnace door before heating. It is not recommended to open the furnace door when the temperature in the furnace chamber is greater than 400℃.

4 It is not recommended to use the machine under the positive pressure. If you want to use positive pressure, the pressure must never exceed 0.02MPa, otherwise it will cause damage to the furnace chamber.

5 Regularly check whether each electrical connection part of the temperature control system is in good contact, especially the connection of each connection point of the heating element.

6 Suggested heating rate: <1000℃, 10℃/min; 1000-1500℃ not exceeding 5℃/min; after 1500℃ not exceeding 2℃/min, otherwise the furnace chamber and heating elements will be damaged.

7 When the equipment is cooling down, please use the program to cool down and set the cooling program. It is not recommended to directly “stop” to cool down. For a high temperature furnace of 1800 degrees, the cooling rate is recommended not to exceed 3℃/min, otherwise the furnace chamber will be damaged. Please do not turn off the power of the device if the temperature of the device is above 500℃ to prevent safety problems.

Security Maintenance

- The power must be cut off before maintenance or inspection.

- If the product body is damaged, please stop using it. If the product body is damaged and used continuously, it may cause fire, electric shock and other accidents.

- Only qualified personnel can replace parts. It is strictly forbidden to leave thread or metal objects in the equipment, otherwise there is a danger of explosion and fire.

- After replacing the instrument or circuit board, the parameters must be adjusted and matched before operation, otherwise there is a danger of property damage.

- The control circuit part of the equipment should be checked regularly (checked once every six months), and the circuit should be fastened. If there is any disconnection of the insulating layer or disconnection of the wiring, it should be handled in time, otherwise it will cause a short circuit of the equipment or a fire hazard.

Cautions

- If the warnings listed beloware ignored, it may cause fire or personal injury.

- Do not touch the inner or outer surface of the furnace body during use or within a period of time after use to prevent burns.

- Do not place vases, bonsai, cups, cosmetics, medicines, metal objects, etc. on the product body.

- Do not damage the power cord. If the power cord is damaged, it may cause fire, electric shock, and other accidents.

- It is forbidden to modify the power cord at will or bend, twist or stretch the power cord bluntly. It may cause fire and electric shock.

- When smoke, foreign matter or water enters the product body, please turn off the power switch, unplug the plug, and ask professionalsto inspect and repair it.

- It is strictly forbidden to plug and unplug the power supply when hands are wet, which may cause electric shock.

- Do not place flammable or explosive materials within one meter around the product to prevent fire.

- Do not let children touch this product. The temperature of the case may cause burns.

- It is forbidden to decompose and transform the body at will. It may cause injury, malfunction, or fire.

- The upper cover can be opened only after the temperature in the furnace becomes normal. At this time, the furnace temperature may still be high, please wear high-temperature gloves for operation.

Note: This equipment does not recommend or advocate the use of flammable, explosive, toxic and harmful gases.

Packing and Delivery

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Reviews

There are no reviews yet.