Product Description

Basic constitution: The column cylinder is equipped with outside heating mantle, rotor and inside condenser. The fixing frame of rotor is precisely equipped with scratch film and anti-splash device. The inside condenser is placed in the center of evaporator, and the rotor should rotor between column cylinder and condenser.

Distillation process:The material should add from the top of evaporator and continuously spread to the heating surface through the material covered on rotor. Then, the scratch film is capable of scratching the material into a thin and flowing liquid film. During this process, the light molecular exceeded the heating surface form the condense liquid on inside condenser without any collision. Then, the molecular flows along the condenser tube, and discharge through the discharge tube on the bottom of evaporator. The residue liquid (heavy molecule) is collected on the circular channel under the heating zone, and flows through the discharge tube on one side.

When the operating vacuum is about 500 Pa, it is capable of conducting in the scratch film evaporator or falling film evaporator. However, if the distillation is operate under the high vacuum status ( for instance, the pressure ranges from 0.001 to 100Pa), problems are bound to cause. Therefore, it is necessary to choose the evaporator which the vapor pressure id no less than pressure difference caused by heating and cooling surface, and the evaporator quipped with outside condenser is excluded from the distillation process under the high vacuum range.

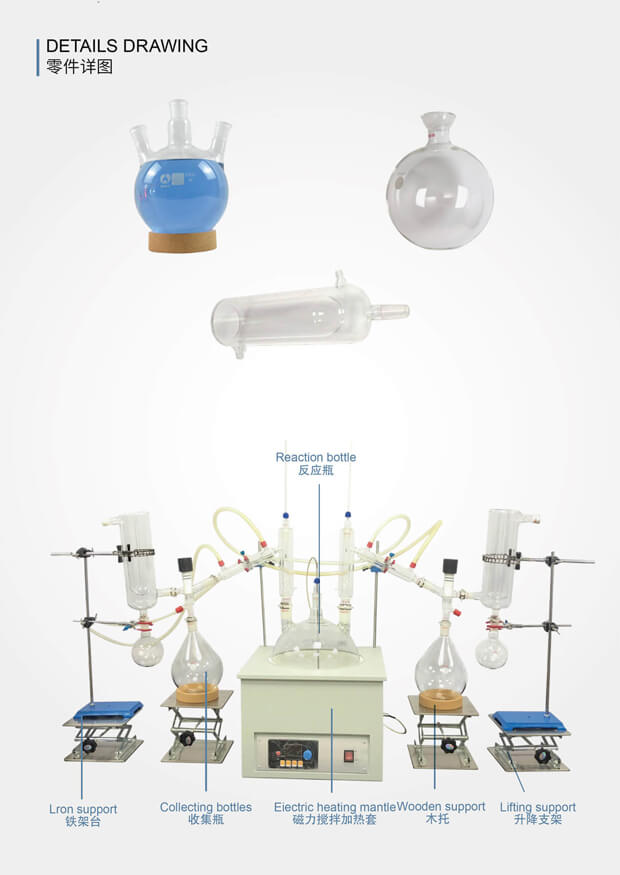

Product Details

Adopt three ports reaction bottle, with a special feeding port, which is convenient for feeding.

Micro vertical spine distiller, vertical spine structure, used for fractionation function; Vacuum sandwich is used to weaken the influence of wind and greenhouse to maintain the appropriate temperature gradient in the column.

Glass parts are connected by frosted mouth, which is easy to operate and has good sealing.

Vacuum valve can be equipped on the Micro vertical spine distiller, used for vacuum pumping.

Product Application

(1) Food processing industry: refined edible oil, separating high-value products such as vitamins, sterols, fatty acids and antioxidants.

(2) Cosmetics industry: extract lanolin, spices and other products.

(3) Pharmaceutical industry: natural vitamin A and vitamin E as well as natural medicines including sedatives.

(4) Coatings and paint industry: Improve the drying performance and hardness of polymer oils such as sesame oil and linseed oil.

(5) Epoxy resin production: lighten the color of the epoxy resin, reduce the viscosity, and prolong the storage life.

(6) Silicon production: Easily remove low molecular weight or high molecular weight polymers from polymer blends.

(7) Wax production industry: purification of natural paraffin, beeswax, palm wax and some microcrystalline waxes and high melting waxes.

(8) Surfactant production industry: the extraction of glycolipids, polyoxyalkylene glycols, and natural fatty acid and fatty acid wax products.

(9) Mineral oil production: used in high temperature lubricating oils and greases, generally extracted from petroleum residue C/35 ~ C / 100 fractions.

Product Parameters

| Short-Path Distillation | ||||

| Model | SD-2 | SD-5 | SD-10 | SD-20 |

| Material | G3.3 | |||

| Heating Capacity(ml) | 2000 | 5000 | 10000 | 20000 |

| Heating temperature(℃) | Room temperature -250 | |||

| Accuracy(℃) | ±1 | |||

| Vaccuum Degree(Mpa) | 0.098 | |||

| Working temperature(℃) | 5-40 | |||

| Voltage | 220V/50Hzor110V/60Hz | 380V/50Hz | ||

| Package Size | 450*450*600 | 580*580*735 | 850*850*600 | |

| Weight | 18 | 24 | 30 | |

Product Parts

1.Distilled bottle

2.Electric heating mantle

3.Lifting platform

4.Cold trap

5.Collection bottle

6.Thermometer

7.Reaction bottle

Quality Certification

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.