Description

As a type of thermodynamic separation technology, the equipment can evaporate components with low boiling points by utilizing that the boiling point of each component in the mixed liquid or liquid-solid mixture is different, and then condense the material to separate the whole components. It is the combination of evaporation and condensation unit operations as well as a kind of liquid-liquid separation technology.

Advantages of Distillation

Compared to other separation methods, such as extraction, filtration and crystallization, it has the advantage that no other solvents than system components are required, thus ensuring that no new impurities are introduced.

Product Features

- A large quantity of distillation;

- Heat and high temperature resistance;

- Excellent sealing performance;

- High transparency;

- Steady and firm material;

- Intelligent temperature control, and magnetic stirring.

Product Advantages

- The sensor is upgraded. There is a casing pipe outside the thermometer for contacting materials indirectly, with a better sealing performance.

- The diameter of the vacuum pumping becomes large to obtain higher vacuum degree and improve the pumping speed.

- The discharge method is optimized, easier to operate. (One sustainable discharge valve replaces three fractional distilling flasks.)

- It has a higher evaporation efficiency.

- The large distiller is adopted, enhancing the evaporation area and capacity.

Accessories Diagram

Accessories List of 10L Short Path Distillation Equipment |

|||||

| No. | Name of Parts | Specification | Quantity | Unit | Notes |

| 1 | Double-Mouth Reaction Flask | 10L | 1 | piece | |

| 2 | Distiller | custom-made model | 1 | piece | |

| 3 | Connecting Valve | 1 | piece | ||

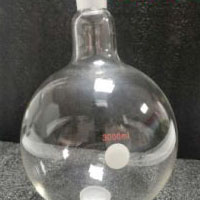

| 4 | Round-Bottom Flask | 3000ml | 1 | piece | |

| 5 | Cold Trap | 2 | pieces | ||

| 6 | Cold Trap Cover | 2 | pieces | ||

| 7 | Receiving Flask | 500ml | 2 | pieces | |

| 8 | Connecting Pipe | 1 | piece | ||

| 9 | Temperature Casing | 2 | pieces | ||

| 10 | Temperature Measuring Glass Tube 1 | 1 | piece | long pattern | |

| 11 | Temperature Measuring Glass Tube 2 | 1 | piece | short pattern | |

| 12 | Hollow Plug | 2 | pieces | ||

| 13 | Funnel | 110mm | 1 | piece | |

| 14 | Temperature Gauge | 1 | piece | ||

| 15 | Vacuum Gauge | 1 | piece | ||

| 16 | GL14 Cover | 3 | pieces | ||

| 17 | Stainless Steel Flask Clamp 1 | 1 | piece | ||

| 18 | Stainless Steel Flask Clamp 2 | 10 | pieces | ||

| 19 | Lifting Platform | 1 | piece | stainless steel | |

| 20 | Iron Support 1 | 1 | piece | ||

| 21 | Iron Support 2 | 1 | piece | ||

| 22 | Cross Bar | 2 | pieces | stainless steel | |

| 23 | Cross Clamp 1 | 8 | pieces | ||

| 24 | Cross Clamp 2 | 5 | pieces | ||

| 25 | Three-Jaw Clamp | 3 | pieces | ||

| 26 | Experimental Chain Clamp | 2 | pieces | ||

| 27 | Adapter | 1 | piece | PTFE | |

| 28 | Heating Mantle | 220V/110V | 1 | piece | |

Product Parameters

|

Short Path Distillation and Extraction Equipment |

|

| Application Scope | Liquid mixture. Each component with different boiling points that vary greatly. |

| Specifications | 2/5/10/20L |

| Product Material | High Borosilicate Glass |

Product Details

The electronic contacting thermodetector is adopted, which is sensitive, fast and accurate. The temperature display is more intuitive, with the functions of maximum, minimum, average, unit conversion and HD backlight.

The digital electronic vacuum pump is adopted, with a large screen for displaying intuitively at real-time. It has the accurate range and different interfaces suitable for various occasions, which is easy to operate.

The distiller adopts the special design of anti-backflow, which can effectively prevent the reflux of condensate, such as the reaction flask. The increased diameter of the distiller can speed up the reaction and distillation and save time.

The spool of the PTFE vacuum valve is made of PTFE material, which is coeeosion resistance and more convenient to open and close. It is convenient to regulate the vacuum degree in the reaction chamber by increasing the pressure relief interfaces.

How to Use the Short Path Distillation Equipment?

In the short path distillation equipment, the light and heavy molecules will escape from the liquid surface to enter the gas phase. Due to the various free paths of light and heavy molecules, molecules of different substances will move at different distances after escaping from the liquid surface. If a condensing plate can be properly set up, the light molecules will be condensed and discharged after reaching the condensing plate, while heavy molecules that can’t reach the condensing plate will be discharged along the mixed liquid. In this way, materials are separated.

When the short path distillation equipment is in the process of mass transfer, the temperature and vacuum pressure condition can be adjusted and controlled suitably at any time. The tower column in the equipment adopts the relatively special design of thermal-stress resistance expansion wrinkle section, which can effectively prevent the temperature difference of the tower column from changing suddenly.

During the operation process of the short path distillation equipment, its condensing surface and thin surface can directly form the pressure difference, which functions as the driving force of the entire steam flow. Any small pressure drop in the equipment will cause the steam flow. During the operation, the distance between the condensing surface and the boiling surface is relatively short.

The short path distillation equipment is required to choose its economical and reasonable distillation temperature so that the material can possess a better stability when it’s processed. There may be collision between the evaporation surface and the condensing surface when the steam molecules are flying from the evaporation surface to the condensing surface.

During the operation, the heat exchange between the environment and columns can totally avoid the traditional way. It will directly lead to the error of experimental data, due to the overheat or heat preservation of equipment causes that the balance is artificially disturbed.

With a high strength in the operation, the short path distillation equipment possesses a strong corrosion resistance, which is greatly applicable for the majority of reagents and chemical materials.

The extremely advanced design concept and manufacturing technology are adopted in the process of design. The key component in the equipment is the distillation tower column. The equipment structure is directly related to the separation effect in the process of use.

The material has a very short dwelling time in the equipment when the short path distillation equipment is used. Thus, the equipment is quite suitable for high viscosity materials. In the process of selection, the better material can be chosen for manufacturing the equipment, which all adopts the quartz glass material with a small coefficient of thermal expansion and relatively stable chemical performance.

Precautions for Use

- Check whether the inlet and outlet valves of the refrigeration equipment are normally opened and whether the pressure is in the normal range.

- Check whether the power supply of each device is turned on.

- With the electric heating, the surface temperature of the external heating body is relatively high. Don’t touch it with your hands to avoid burns.

- Check whether the ethanol in the low and constant temperature tank is enough.

- Check whether the liquid nitrogen in the tank is sufficient.

- Check if the connection between the cold trap and the equipment is greatly sealed.

Reviews

There are no reviews yet.