Industrial Freeze Dryer Parameter

| Parameters | Model | FDGY-0.5 | FDGY-10 | FDGY-20 | FDGY-50 | FDGY-100 | FDGY-150 | FDGY-200 | FDGY-280 |

| Drying area | 0.5 | 10 | 20 | 50 | 100 | 150 | 200 | 275 | |

| (m2) | |||||||||

| Mean dehydrating amount (kg/h) | 0.6 | 12 | 20 | 50 | 100 | 150 | 200 | 275 | |

| Size of material tray | 310×540×30 | 745×635×30 | 435×555×30 | 540×635×30 | |||||

| (m) | |||||||||

| Number of material tray (pcs) | 3 | 21 | 80 | 144 | 288 | 480 | 576 | 792 | |

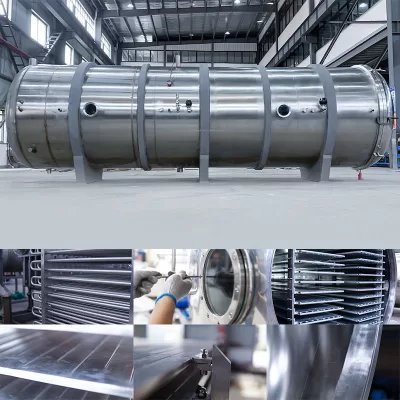

| Size of pot | 1.5×1.6×1.6 | φ1.4×2.1 | φ1.8×2.4 | φ2.4×4.8 | φ2.4×8.9 | φ2.4×12.8 | φ2.4×16.6 | φ2.4×21.9 | |

| (M) | |||||||||

| Operation vacuum | 13.3~200 | 26.6~200 | |||||||

| (pa) | |||||||||

| Heating plate T | Normal temperature~+120°C | ||||||||

| (°C) | |||||||||

| Electric heating | 2 | 21 | 40 | ||||||

| (Kw) | |||||||||

| Steam consumption | 140 | 270 | 450 | 540 | 750 | ||||

| (Kg/h 0.7Mpa) | |||||||||

| Cold load consumption | 1.5 | 21.6 | 36 | 90 | 180 | 280 | 360 | 490 | |

| (Kw) | |||||||||

| Installed power | 6.5 | 55.8 | 104.5 | 41.2 | 69.7 | 92.5 | 117.5 | 125.5 | |

Industrial Freeze Dryer Introduction

An industrial freeze dryer is a specialized equipment used for preparing dried products. It finds wide applications in industries such as food, pharmaceuticals, chemical engineering, biotechnology, etc., to convert liquid or semi-solid substances into dried powders or solid forms through a process involving freezing and vacuum drying.

Industrial Freeze Dryer Features

- Working Principle: Industrial freeze dryers utilize two key steps—freezing and vacuum—to achieve the drying process. Firstly, the substance is frozen into a solid state, and then heat is applied in a vacuum environment. This causes the frozen moisture to transition directly from a solid to vapor state, bypassing the liquid phase, thus achieving rapid drying.

- Application Fields: Industrial freeze dryers play a vital role across various industries. In the food sector, they are employed to create freeze-dried foods that retain nutritional content, taste, and texture. In pharmaceuticals, they produce stable powdered drugs, extending their shelf life. Furthermore, they are used for producing biologics, enzymes, cell cultures, and more.

- Industrial Scale: Industrial freeze dryers typically come with larger drying capacities, suitable for large-scale production. Different models offer varying drying capacities and production capabilities to meet specific needs.

- Temperature and Pressure Control: The equipment is equipped with precise temperature and pressure control systems to ensure optimal conditions during the drying process. This aids in preserving the quality and activity of the products.

- Operation and Monitoring: Industrial freeze dryers often incorporate advanced automation and monitoring systems, capable of tracking and recording various parameters of the drying process, ensuring controlled and reproducible operations.

- Product Quality: The freeze-drying process effectively removes moisture from the product, preventing the growth of microorganisms and enzymes, thereby maintaining the long-term stability and activity of the product.

Industrial Freeze Dryers Application

- Freeze-Dried Foods: Industrial freeze dryers are commonly used to produce a wide range of freeze-dried foods, including fruits, vegetables, meat, seafood, and dairy products. The freeze-drying process removes moisture while retaining the food’s original shape, color, and nutrients, resulting in lightweight and shelf-stable products.

- Instant Coffee and Tea: Freeze-drying is a preferred method for producing instant coffee and tea products. It preserves the delicate flavors and aromas of the beverages, allowing consumers to easily rehydrate the product with hot water.

- Herbs and Spices: Freeze drying is applied to preserve the vibrant colors, flavors, and aromas of herbs and spices, making them suitable for long-term storage without losing their potency.

- Ready-to-Eat Meals: Industrial freeze dryers are used to create ready-to-eat meals for outdoor activities, emergency situations, and space missions. These meals can be rehydrated quickly with water, offering convenience without sacrificing taste or nutrition.

- Baby Food: The technology is employed to produce freeze-dried baby food, maintaining essential nutrients and flavors without the need for preservatives.

- Bakery Products: Freeze-dried fruits and other ingredients are incorporated into bakery products, adding natural flavors and textures to items like cakes, cookies, and pastries.

- Nutritional Supplements: Freeze-drying helps preserve the nutritional content of vitamins, minerals, and other dietary supplements.

- Snack Foods: Industrial freeze dryers are used to create unique and healthy snack options, including freeze-dried fruits, yogurt bites, and vegetable chips.

- Space and Military Rations: Freeze-dried foods are used in space missions and military rations due to their lightweight, long shelf life, and minimal waste characteristics.

- Gourmet Ingredients:High-end restaurants and culinary professionals use freeze-dried ingredients to enhance dishes with intense flavors and innovative presentations.