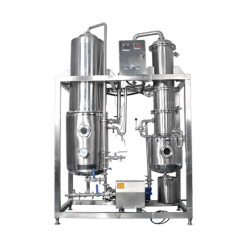

A falling film evaporator refers to a concentration and evaporation device used in industries. As the highly efficient evaporation equipment, falling film evaporators are more and more well-received. It’s widely used in a great number of fields, such as the pharmaceutical, food, chemical, light fields and other fields for the evaporation and concentration of water and organic solvents. And falling film evaporators are especially suitable for the evaporation and concentration of thermal sensitive materials. It can operate continuously under the conditions of vacuum and low temperature, featuring the high evaporation efficiency, energy conservation and low operating cost. As well, materials can be ensured not to change easily during the evaporation. In the following parts, the main applicable fields of falling film evaporators will be introduced in detail.

Applications of a Falling Film Evaporator

1. Food Field

Many of the natural foods contain about 78% to 87% of water, and one of the means used to remove most of the water is evaporation and concentration. Falling film evaporators are very popular in evaporating and concentrating water out of food. The technology to remove water in the food industry has a long history, but the problems are far more complicated than the evaporation and concentration of most chemical products, because the final product not only focuses on physical properties, chemical properties, but also focuses on biological and sensory testing and evaluation. There are many parameters that are difficult to define so far, such as taste, smell, color and tissue state, etc., which should be considered in process design and equipment design. Falling film evaporator is widely used by people to remove water from many kinds of food.

2. Vitamin C Field

The single effect graphite tube rising film evaporator concentrates the vitamin C raw material, which not only has good product quality, but also reduces operating costs and maintenance costs. The use of falling film evaporator is very meaningful for promoting the development and technological progress of the vitamin C industry.

3. Xylose Field

As a new sweetener raw material, xylose has been widely used in the candy, pastry and beverage industry in recent years. However, due to its long production process, high energy consumption and high cost, xylose has developed its market growth rate slowly. Reducing production costs is an important way to increase the amount of xylose used. At present, steam consumption accounts for about 50% of the cost of xylose production. How to reduce steam consumption is one of the main tasks to achieve. The falling film evaporation system fully recovers the waste heat lost in the hydrolysis process, reduces the steam consumption in the hydrolysis and primary evaporation processes, reduces the production cost, and improves the economic benefits of the enterprise. After the factory runs the test, the evaporator proves that the process design is reasonable, the investment is saved, the benefit is obvious, and it has good promotion and use value in the sugar industry.

Parts of a Falling Film Evaporator

As an efficient evaporation equipment, a falling film evaporator mainly consists of following parts.

- Feed part: where users put in the sample materials through a small horizontal pipe.

- Heat part: which is to heat the sample materials in order to separate solvents in the mixtures through their different boiling points, in this part, users can adjust the temperature of heating part according to the solvents’ boiling points. The liquid is liquid film type flow evaporation, so it has high thermal efficiency and costs a short heating time.

- Steam condensate: which is to condensate the film that has not been evaporated.

- Concentrate part: which is to concentrate the separated materials into a thicker state.

How does a Falling Film Evaporator Work?

The materials are added from the upper part of the heating tube. They are evenly distributed into each falling film pipe through the distributor, and flow down the wall of the pipe in the state of a liquid film. Under the action of gravity and the secondary steam flow, the materials get evaporated while flowing down. At the bottom of the falling film tube, the materials and secondary steam are basically separated, and they reach the separation chamber to achieve complete separation.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

-

FFE 200L Single-Effect Falling Film Evaporator

Read more -

20L Falling Film Evaporator

Read more -

50L Single-Effect Falling Film Evaporator

Read more -

S212-200L Double-Layer Glass Reactor

Read more -

DLSB-200/40 Low Temperature Coolant Circulation Pump(Chiller)

Read more -

R-1020 Double Cold Trap Rotary Evaporator

Read more

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/falling-film-evaporator-problems/3661.html

https://www.rotovap.cn/falling-film-evaporator-problems/3543.html

https://www.rotovap.cn/falling-film-evaporator-problems/3160.html